Basic Info.

Product Description

12kv High Voltage Vacuum Interrupter Ceramic Tubes Vacuum Bubble for Circuit Breakers

The working principle of vacuum interrupter

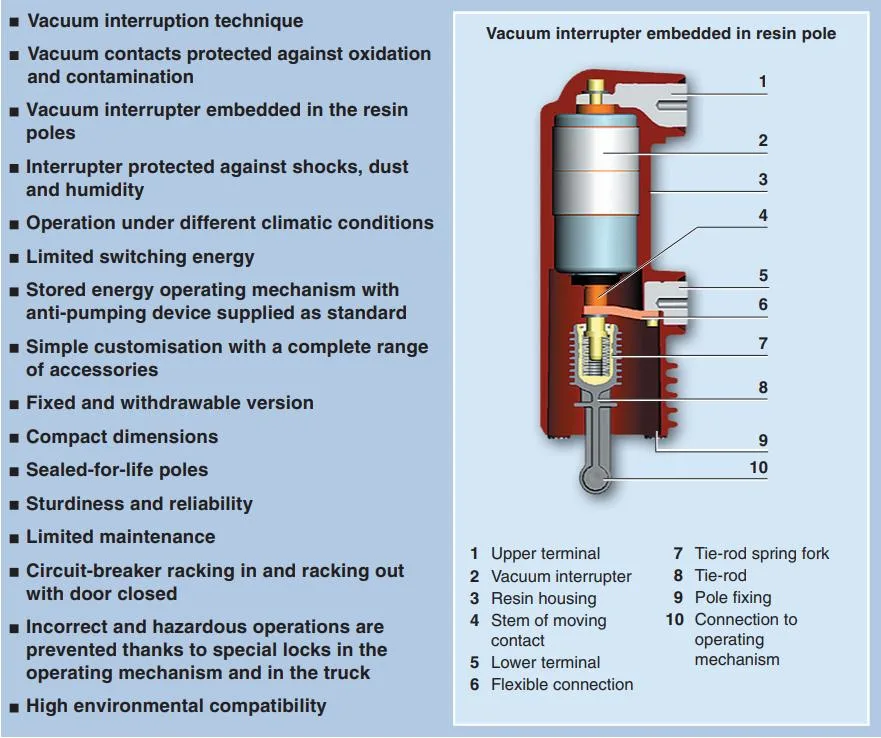

Vacuum interrupters are generally composed of insulating shells, bellows, contacts, conductive rods, shielding covers, guide sleeves and other components. The shell of the vacuum interrupter is not only a vacuum container, but also an insulator between the moving and static contacts.

The bellows is an alloy elastic element with a corrugated wall, which can be elongated or shortened along its axis under the action of external force. The flanges are welded together, and the other port is welded with the movable conductive rod. In this way, by means of the axial expansion and contraction of the bellows, the movable conductive rod can perform axial movement within a certain range without destroying the airtightness of the casing. In the vacuum interrupter, the outside of the bellows is vacuum, and the inside is the atmosphere. There is an atmospheric pressure difference between the inside and outside of the bellows. This pressure makes the moving contact and the static contact press together to form the contact self-closing force.

The main function of the shield is to shield the metal vapor and metal droplets generated in the process of breaking the current. During the current breaking process of the contacts, the vacuum arc between the contacts causes the contact material to generate metal vapor and droplets (arc products). ) sprayed around, these arc builders will deposit primarily on the inner surface of the shield. Without a shield, arc builders can deposit on the insulating housing, destroying the insulation of the housing. The shield also prevents arc builders from reflecting back into the contact gap, causing post-arc re-ignition and heavy breakdown. The shielding cover can also distribute the electric field inside the vacuum interrupter more evenly, thereby improving the insulation level of the vacuum interrupter.

The dynamic and static conductive rods are the inner contacts and the outer conductors connected with the main circuit. One end of the static conducting rod is connected with the static contact by brazing, and the other end is connected with the fixing plate by brazing. The fixing plate is used to fix the vacuum interrupter to the vacuum circuit breaker, and to connect the static conductive rod of the vacuum interrupter to the main circuit. One end of the movable conductive rod is connected to the movable contact by brazing. The movable conductive rod passes through the bellows and the guide sleeve and extends out of the casing. The diameter of the extended part of the movable conductive rod is small, which is used to install the conductive clip. There is a screw hole in the center of the end, which is used to connect with the mechanical operating system, and the moving conductive rod drives the moving contact to move along the axial direction to complete the closing and opening actions.

The guide sleeve mainly ensures the linear movement of the movable conductive rod, and prevents the movable conductive rod from being twisted to damage the bellows and cause the vacuum of the arc extinguishing chamber to leak.

Schematic diagram of the structure of the vacuum interrupter

|

Application

FAQ

Q: Could I have prices of your products?

A: Welcome. Please feel free to send us inquiry here. We will reply you within 24 hours.

Q: Can I get a sample before the bulk order?

A: Yes, we welcome sample order to test and check quality.Mixed samples are acceptable.

Q: Can we print our logo/ company name on products?

A: Yes, of course, we accept OEM, then need you to provide brand authorization to us

Q:Do you accept product customization?

A:Yes, of course, please provide specific drawings or parameters, we will quote you after evaluation

Q: What is the lead time?

A: The lead time depends on the quantities ordered, generally within 7-20 days after receiving the payment.

Q: What is your Trade Terms?

A: We accept EXW, FOB, CIF, FCA, etc.

Q: What is your payment method?

A: We accept T/T, Western Union, Paypal, irrevocable L/C at sight, etc

Q: Do you inspect the finished products?

A: Yes, each step of production and finished products will be came out inspection by QC department before shipping. And we will provide goods inspection reports for your reference before shipment

Q: How to solve the quality problems after sales?

A: Take photos of the quality problems and send to us for our checking and confirming, we will make a satisfied solution for you within 3 days.