Basic Info.

Model NO.

MSVC/MCR

Larger Capacity of MCR Branch

50000kvar

MCR Adjustment Range

1%-100%

Response Time

80-300ms

Noise

Less Than 65dB

Transport Package

Wooden Case

Trademark

CNKC

Origin

China

Production Capacity

5000/Monthly

Product Description

Product Description

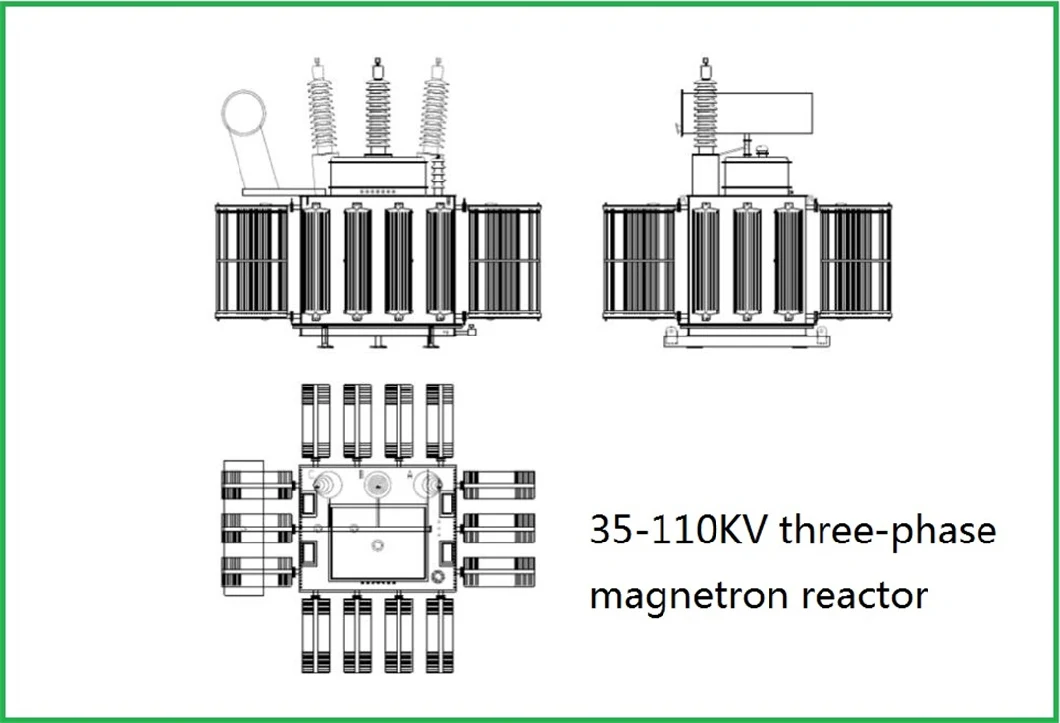

The magnetron reactor type high-voltage static reactive power compensation device (hereinafter referred to as "MCR type SVC device") is suitable for installation in systems with frequent reactive load changes, such as wind power, photovoltaic power stations, electric arc furnaces, rolling mills, mine hoists, electric power High-voltage systems such as locomotives. The product has the characteristics of high reliability, fast response speed, continuous stepless adjustment, small footprint, maintenance-free, etc. It is a very good dynamic reactive power compensation equipment in power system, electrified railway, metallurgy, mining, new energy and other industries.

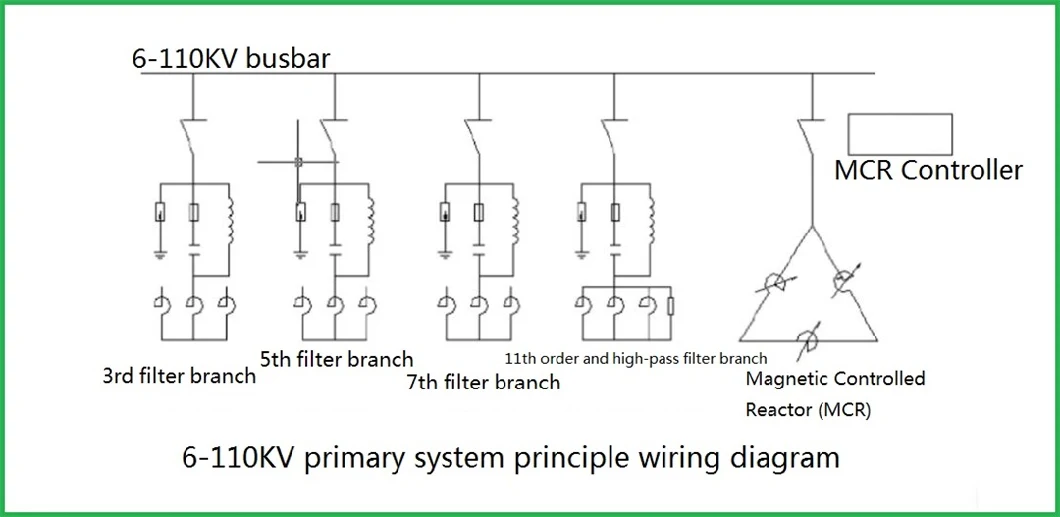

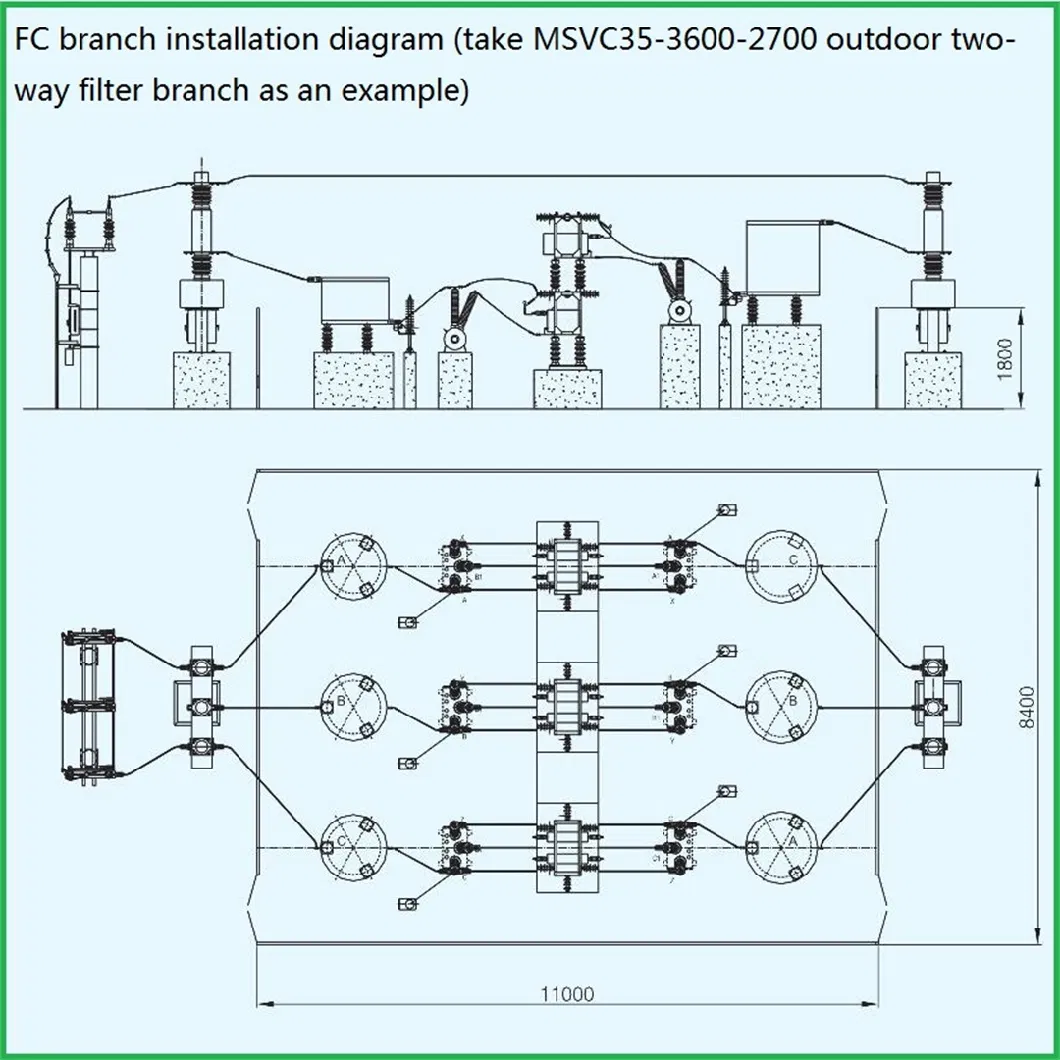

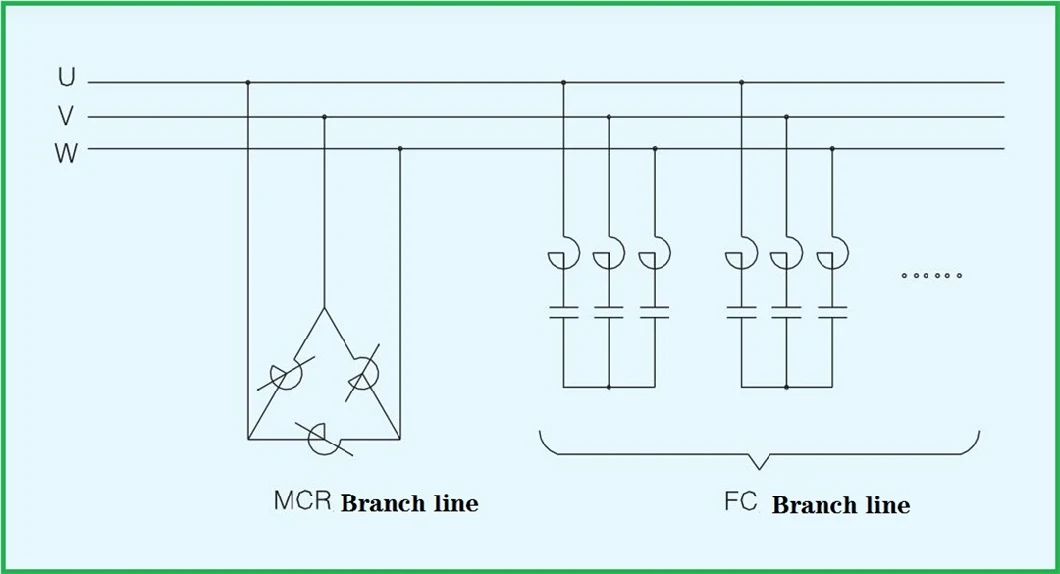

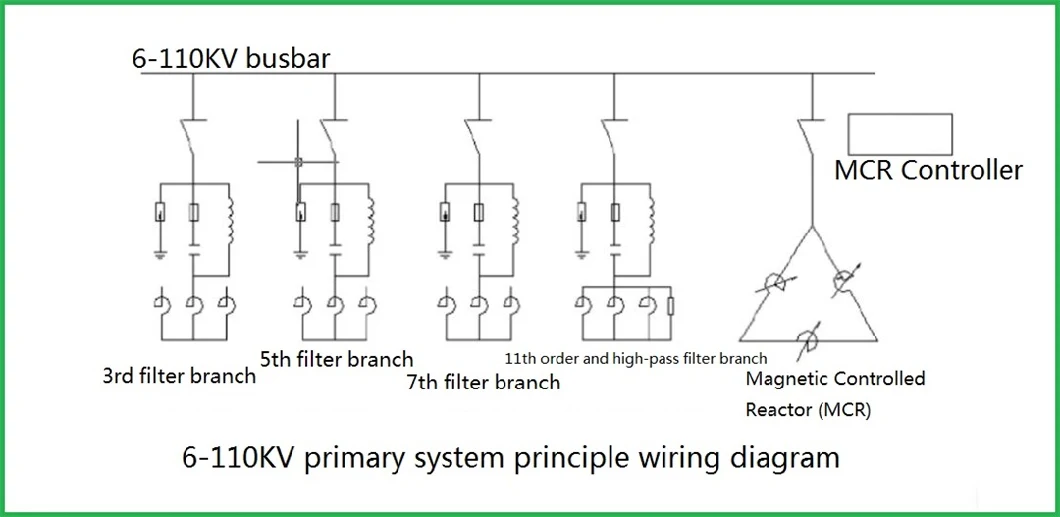

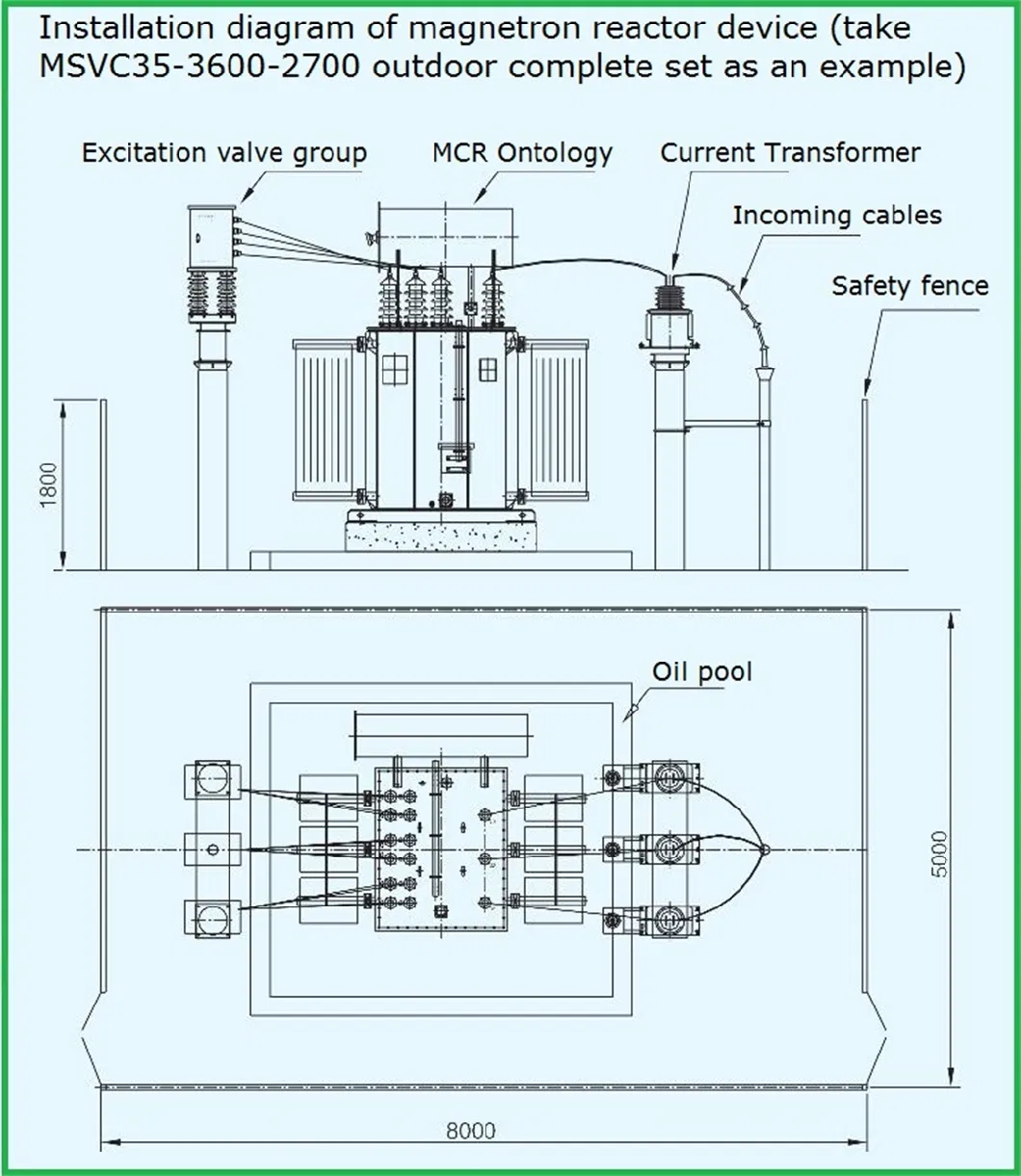

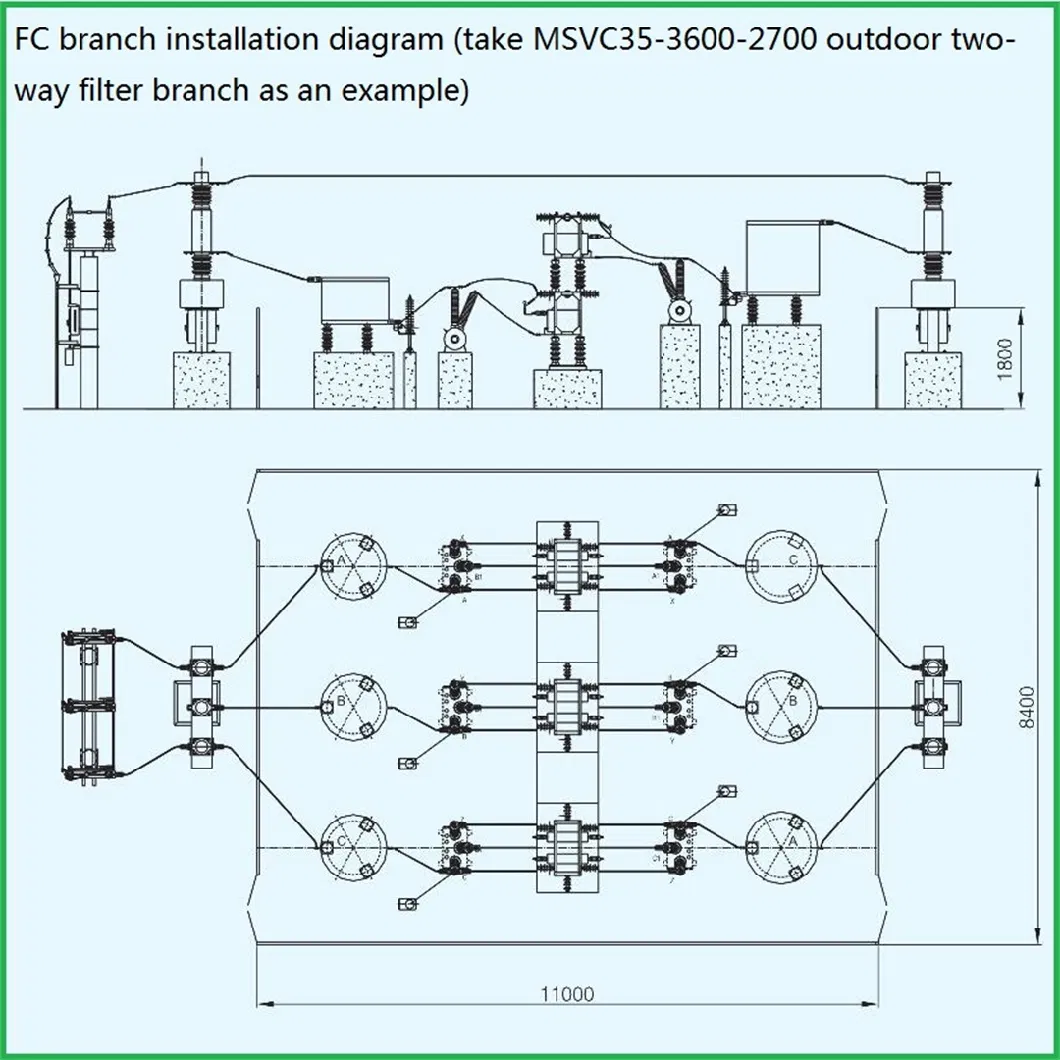

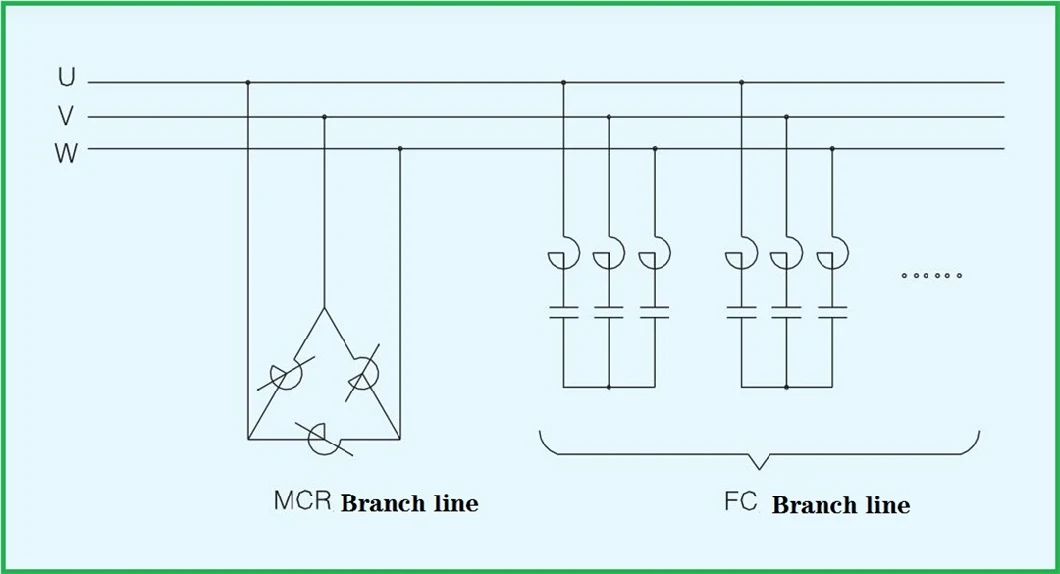

MCR type SVC device is mainly composed of FC filter (or fixed) capacitor branch, MCR magnetron reactor (including MCR body and excitation system), automatic control and protection system. The FC branch is used to provide the capacitive reactive power required by the system , and can also be designed as a multi-channel passive filter to achieve the purpose of harmonic control. The MCR magnetron reactor is used to balance the excess capacitive reactive power generated by the load fluctuation in the system, and stabilize the voltage fluctuation caused by the load impact. The control and protection system is responsible for providing instructions to the reactive power control of the entire system and providing corresponding protection to the entire device.

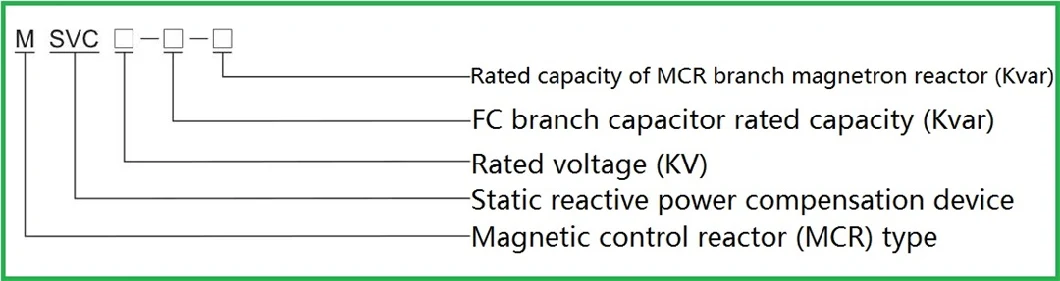

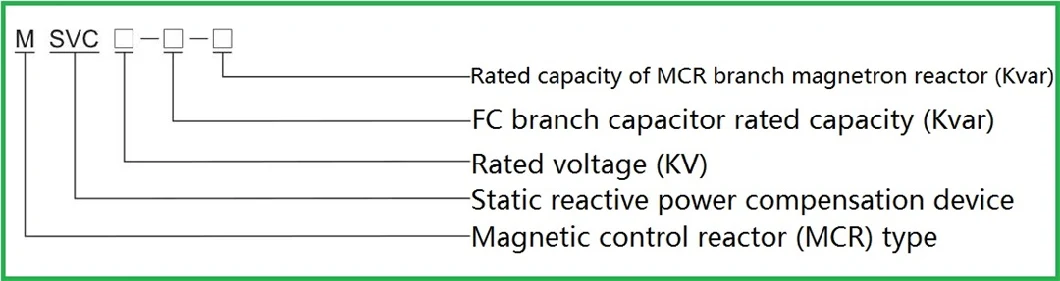

Model Dscription

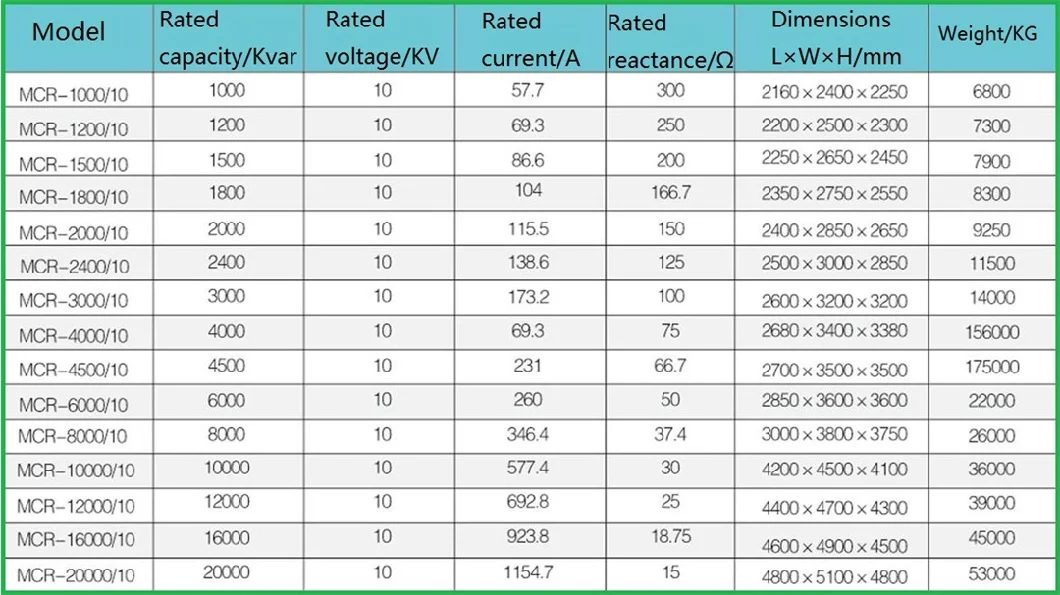

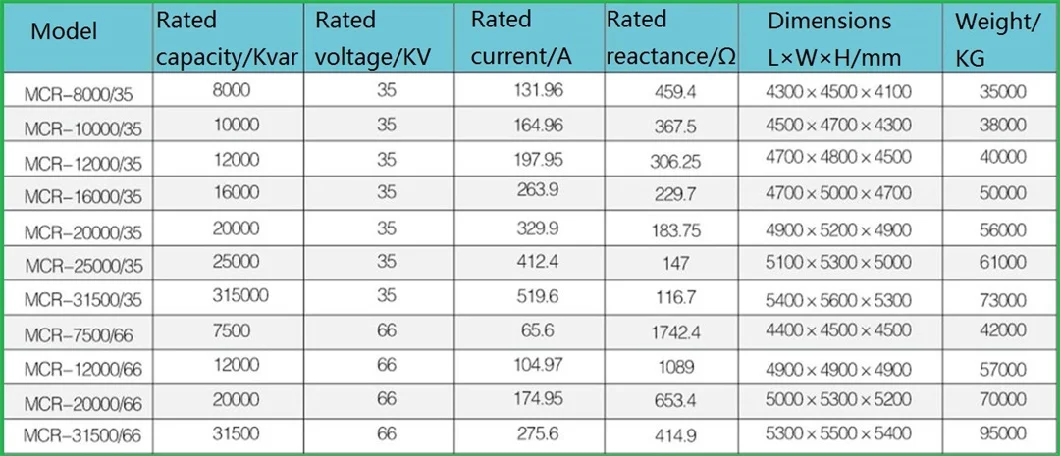

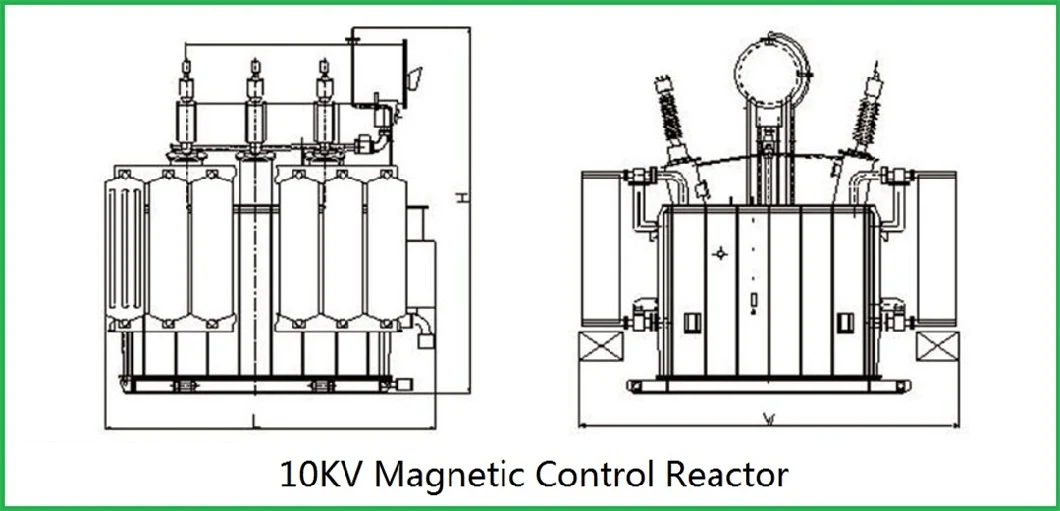

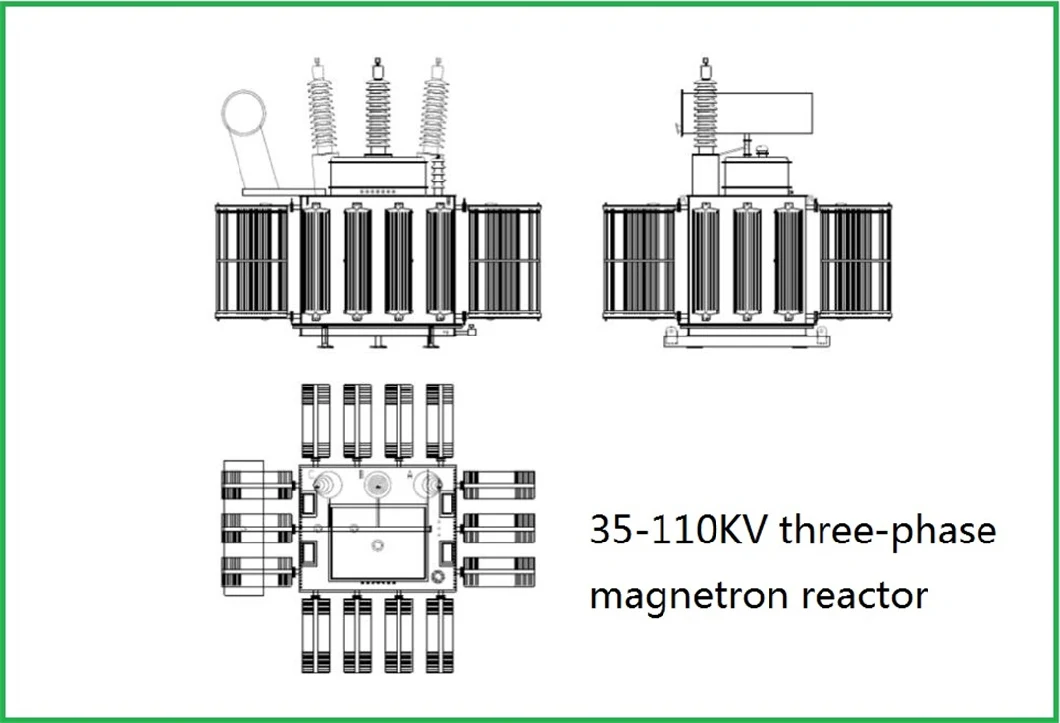

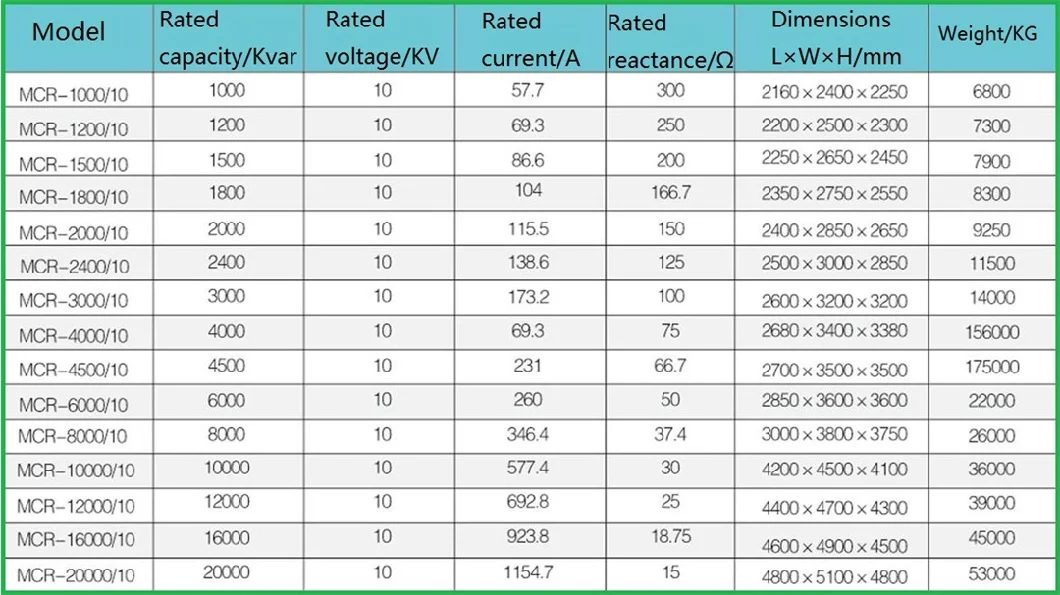

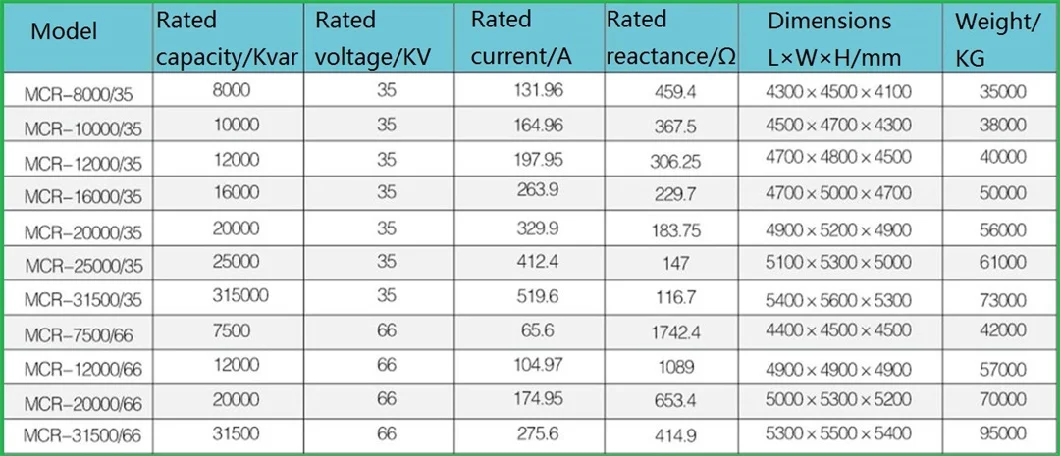

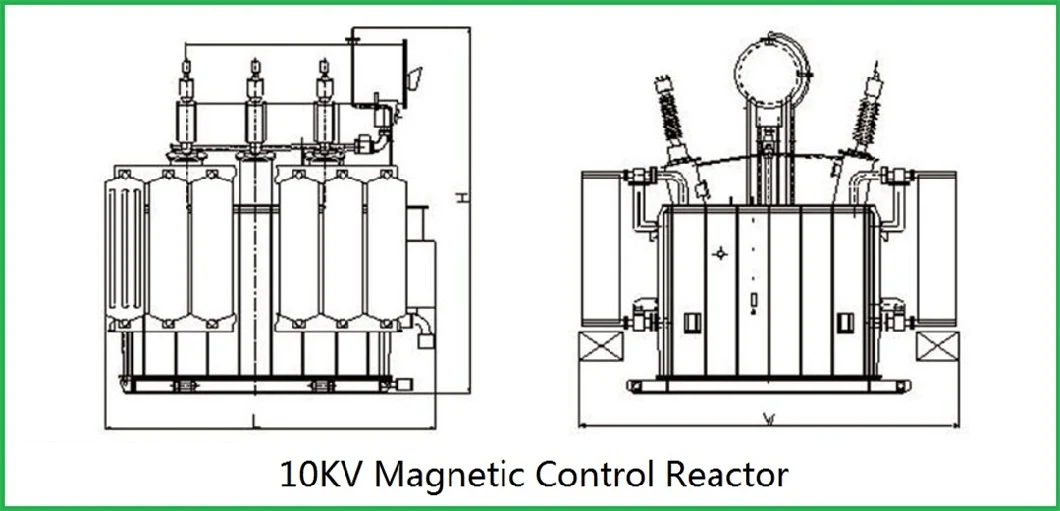

Technical parameters and structure dimensions

1. System rated voltage: 6kV, 10kV, 20kV, 35kV, 66kV, 110KV;

2.Rated frequency: 50Hz

3. Larger capacity of MCR branch: 50000kvar;

4. MCR adjustment range: 1%-100%;

5. Larger capacity of FC branch: 100000kvar;

6. Response time: 80 ~ 300ms.

7.Noise: less than 65dB

8.Cooling method: self-cooling, air-cooling, etc.

9.Loss: 0.3%-0.8%

10.Altitude: ≤1000m (higher than 1000m using plateau)

Product features and scope of use

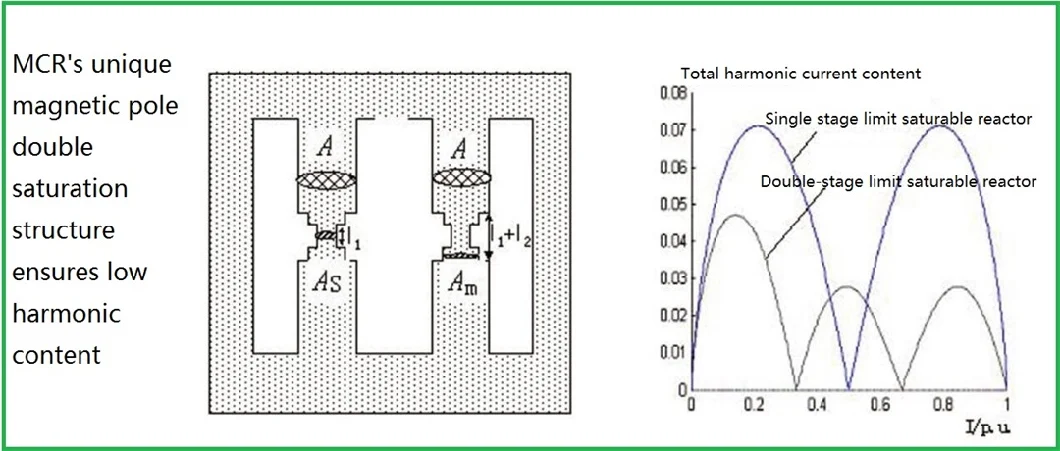

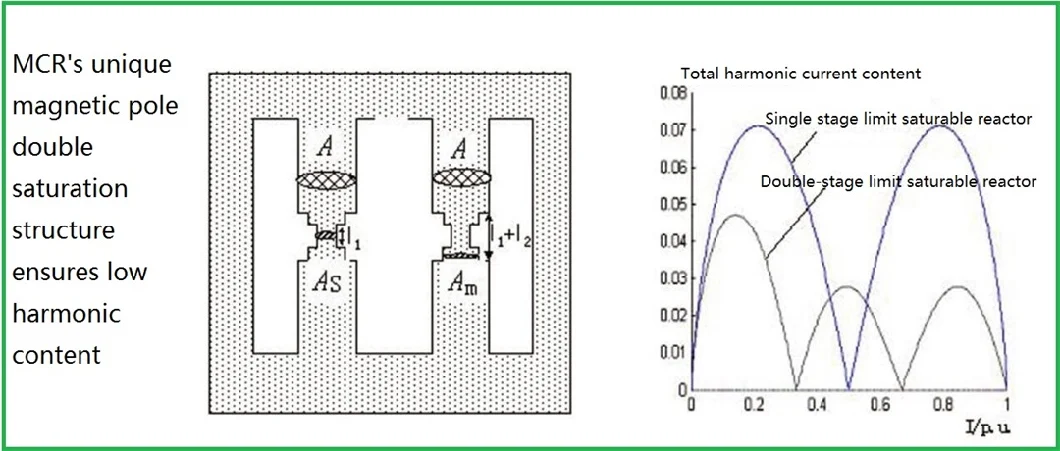

1. Fast tracking reactive power regulation, using "magnetic valve" type controllable saturable reactor (MCR), auto-coupling DC excitation and limit magnetic saturation working mode, which greatly reduces harmonics, and has low active power loss, fast response speed fast feature .

2. The optical isolation phase-shift trigger technology is adopted, and the optical fiber transmission phase-shift trigger improves the insulation level of the system, enhances the anti-interference ability of the device, and reduces the size of the equipment.

3. The control element is a low-voltage thyristor, which does not need to withstand high voltage and large current during operation. It is safe and reliable, and has low calorific value. Natural cooling is required, and no auxiliary cooling equipment is required .

4. Flexible installation methods, both outdoor and indoor installations are available. Small footprint, high reliability, maintenance-free, and long service life.

5. Using multi-CPU parallel processing technology, high degree of automation, can realize various perfect control and protection functions of MCR and FC branch, switch online monitoring, harmonic measurement and control, etc., and can also realize various data transmission and " four" Remote" function. The operation is simple and the user interaction is friendly and convenient.

Application area:

MSVC type dynamic reactive power compensation device is mainly used in 6-220KV power system, which can realize reactive power dynamic compensation, improve power factor, stabilize voltage, and filter harmonics at the same time to improve the power quality of power grid. The device is currently widely used in coal, electrified railways, steel, wind power and other industries, and the power saving effect is obvious.

1. Electric arc furnace

Due to the unstable arc resistance and unbalanced three-phase, the electric arc furnace is mainly harmful to the power grid as follows: the generated Noble components are abundant and the content is large, and the main Noble current components are 2-7 times, among which 2, 3, and 5 times are the largest, the derivative grid is seriously unbalanced in three-phase, negative sequence current is generated, there is serious voltage flicker, and the power factor is low.

The way to completely solve the above problems is that the user must install a dynamic reactive power compensation device with fast response. The MSVC system has a fast response time and can fully meet the strict technical requirements. It can quickly provide reactive current to the electric arc furnace and stabilize the bus grid voltage, increase the output of the active power of the system, improve the production efficiency, and minimize the impact of flicker. The phase-splitting compensation function of MSVC can eliminate the three-phase unbalance caused by the electric arc furnace, and the filtering device can eliminate harmful high-order Noble waves and improve the power factor by providing reactive power to the system.

2. Long-distance power transmission

The power system is currently trending towards high-power grids, long-distance power transmission, and high energy consumption, forcing the transmission and distribution system to increase improvement measures. MSVC can significantly improve the power transmission and distribution performance of the power system, that is, under different power grid conditions, in order to maintain a balanced voltage, MSVC can be installed in one or more appropriate positions in the power grid to achieve the following purposes to stabilize the weak grid system. Voltage: Reduce transmission loss, increase transmission capacity, maximize the efficiency of the existing power grid, increase the transient steady state limit, increase damping under small disturbances, and buffer power oscillations.

3. Rolling mill system

The rolling mill is a reactive impact load, which has the following effects on the power grid: low power factor: causing voltage fluctuation and voltage drop, in severe cases, the electrical equipment can not work normally, reducing production efficiency: harmful high-order harmonics will be generated in the transmission device of the load , mainly the high-order harmonics represented by the 5th, 7th, 11th, and 13th times, which will cause serious distortion of the grid voltage. The MSVC device can solve the above problems well , keep the bus voltage stable, filter out the harmonics, and improve the power factor.

4. Coal mine hoist

Coal mine hoists are mostly driven by DC motors, which have a short working cycle, fast response speed, and large reactive power fluctuations. During operation, they will have the following effects on the power grid: cause grid voltage drop and voltage fluctuations, low power factor, and rectifier devices will produce a lot of high Sub-harmonic, fast response of MSVC device can perfectly solve the above problems.

5. Wind farm

In wind farms, the voltage and reactive power fluctuate greatly under the influence of wind speed, and part of the inductive reactive power is often required to compensate the line charging power. If a fixed or graded switching capacitor bank is used to compensate the system reactive power and improve the power factor, this This method can only provide capacitive reactive power, but cannot achieve fast dynamic adjustment with the change of wind speed, which is easy to cause reactive power to be sent back to the system, increase the voltage, and endanger the stability of electrical equipment and system. The MSVC system can quickly and accurately perform capacitive and inductive reactive power compensation, which can completely solve the problem of reactive power reversal while stabilizing the busbar voltage and improving the power factor. And when the new MSVC system is installed, the original fixed capacitor bank can be fully utilized, and only the magnetron reactor can be added, which can achieve good results with less investment and become a suitable choice for improving the power quality management of wind farms.

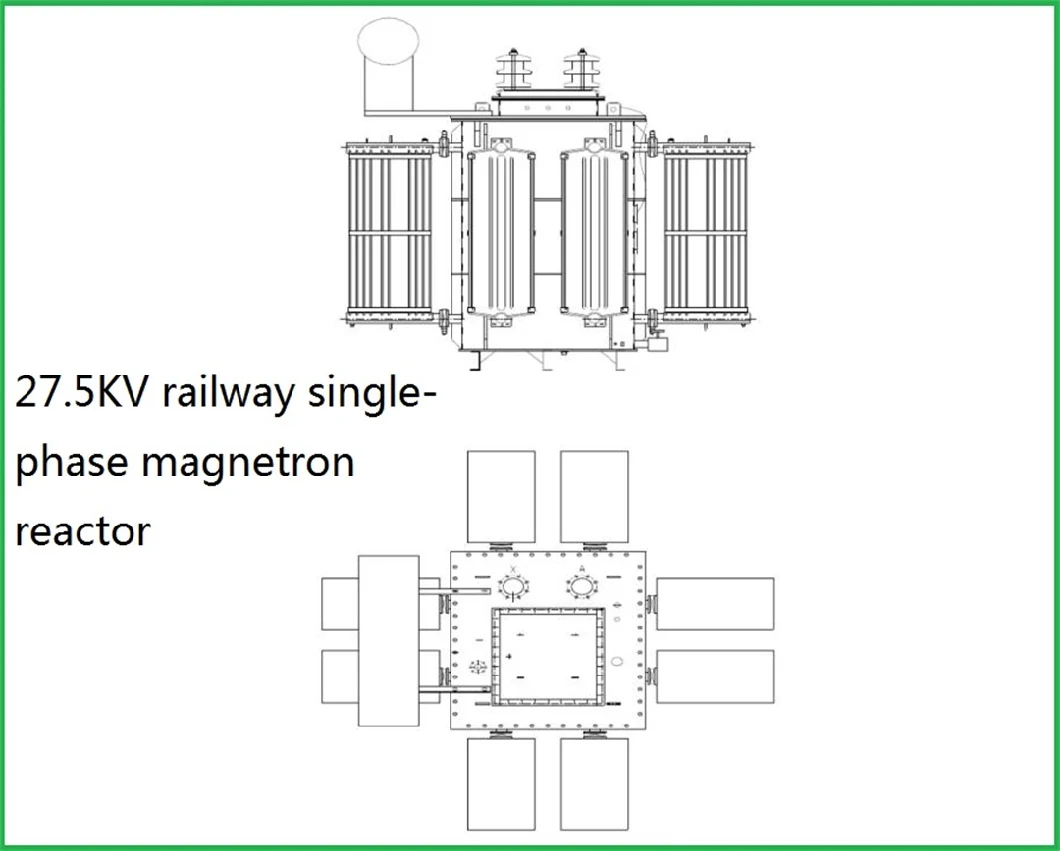

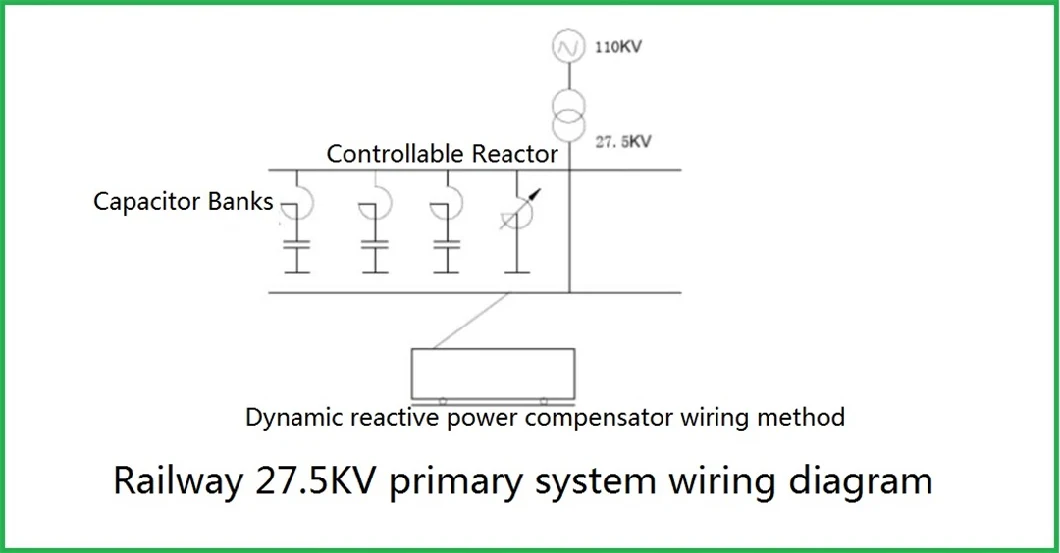

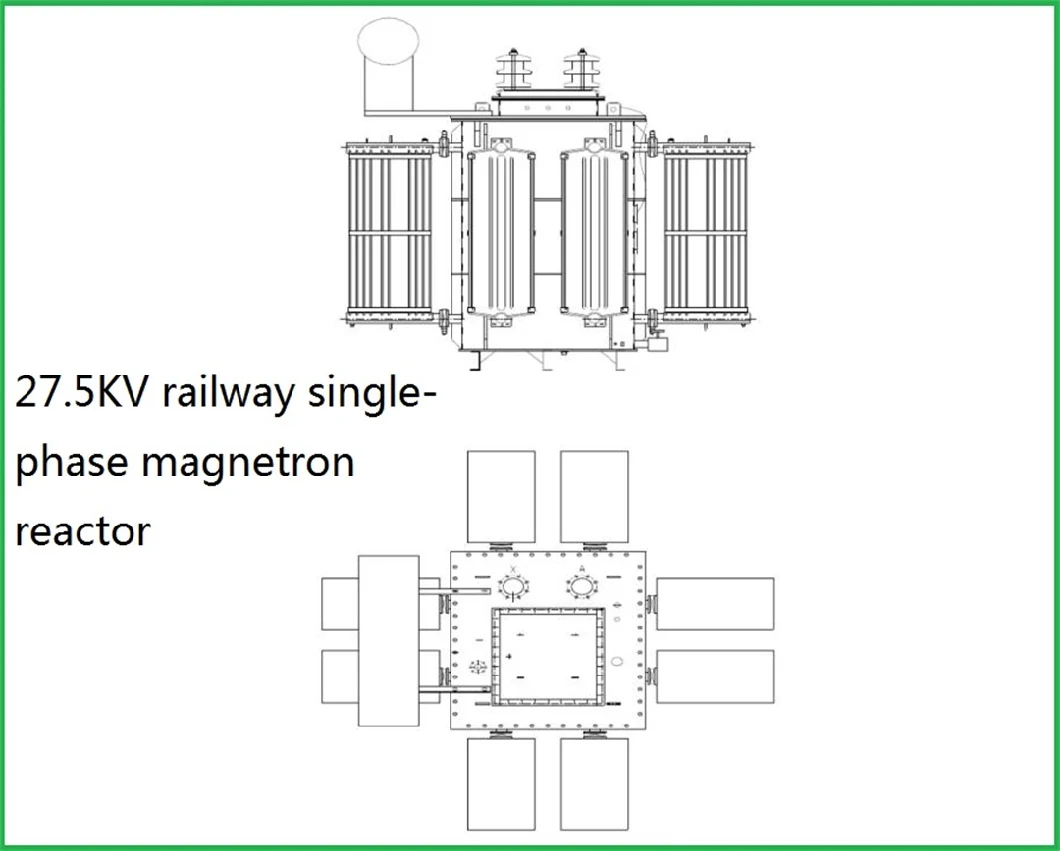

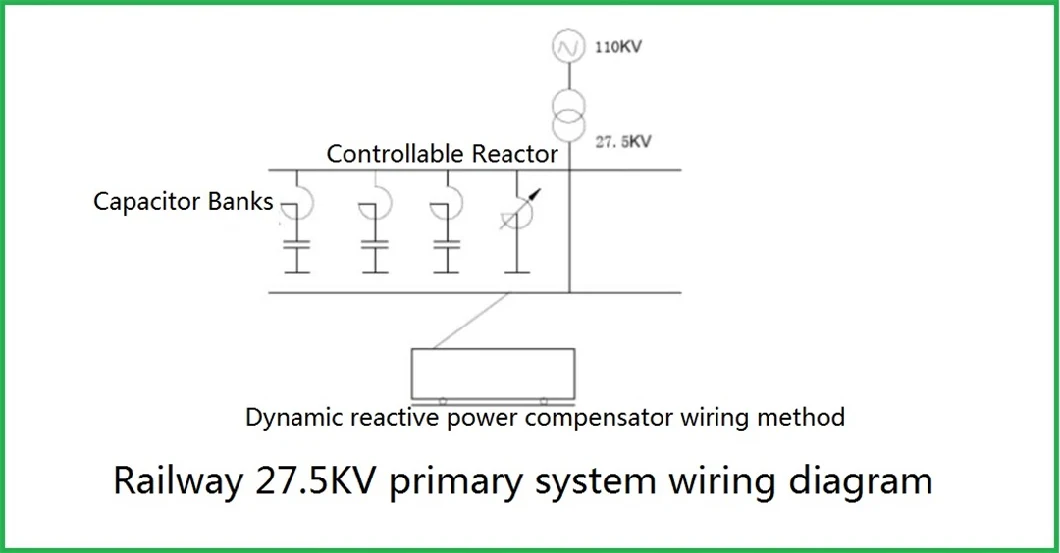

6. Electric locomotive power supply

The electric locomotive transportation mode not only protects the environment, but also causes serious "pollution" to the power grid. The single-phase power supply of trams and locomotives causes serious three-phase imbalance and low power factor of the power supply network, and generates negative sequence current. The current way to solve this problem is to install MSVC at the appropriate position along the railway line to improve the power factor and solve the three-phase unbalance.

Product operating environment and ordering instructions

Product packaging

Product application use

Product application use

The magnetron reactor type high-voltage static reactive power compensation device (hereinafter referred to as "MCR type SVC device") is suitable for installation in systems with frequent reactive load changes, such as wind power, photovoltaic power stations, electric arc furnaces, rolling mills, mine hoists, electric power High-voltage systems such as locomotives. The product has the characteristics of high reliability, fast response speed, continuous stepless adjustment, small footprint, maintenance-free, etc. It is a very good dynamic reactive power compensation equipment in power system, electrified railway, metallurgy, mining, new energy and other industries.

MCR type SVC device is mainly composed of FC filter (or fixed) capacitor branch, MCR magnetron reactor (including MCR body and excitation system), automatic control and protection system. The FC branch is used to provide the capacitive reactive power required by the system , and can also be designed as a multi-channel passive filter to achieve the purpose of harmonic control. The MCR magnetron reactor is used to balance the excess capacitive reactive power generated by the load fluctuation in the system, and stabilize the voltage fluctuation caused by the load impact. The control and protection system is responsible for providing instructions to the reactive power control of the entire system and providing corresponding protection to the entire device.

Model Dscription

Technical parameters and structure dimensions

1. System rated voltage: 6kV, 10kV, 20kV, 35kV, 66kV, 110KV;

2.Rated frequency: 50Hz

3. Larger capacity of MCR branch: 50000kvar;

4. MCR adjustment range: 1%-100%;

5. Larger capacity of FC branch: 100000kvar;

6. Response time: 80 ~ 300ms.

7.Noise: less than 65dB

8.Cooling method: self-cooling, air-cooling, etc.

9.Loss: 0.3%-0.8%

10.Altitude: ≤1000m (higher than 1000m using plateau)

Product features and scope of use

1. Fast tracking reactive power regulation, using "magnetic valve" type controllable saturable reactor (MCR), auto-coupling DC excitation and limit magnetic saturation working mode, which greatly reduces harmonics, and has low active power loss, fast response speed fast feature .

2. The optical isolation phase-shift trigger technology is adopted, and the optical fiber transmission phase-shift trigger improves the insulation level of the system, enhances the anti-interference ability of the device, and reduces the size of the equipment.

3. The control element is a low-voltage thyristor, which does not need to withstand high voltage and large current during operation. It is safe and reliable, and has low calorific value. Natural cooling is required, and no auxiliary cooling equipment is required .

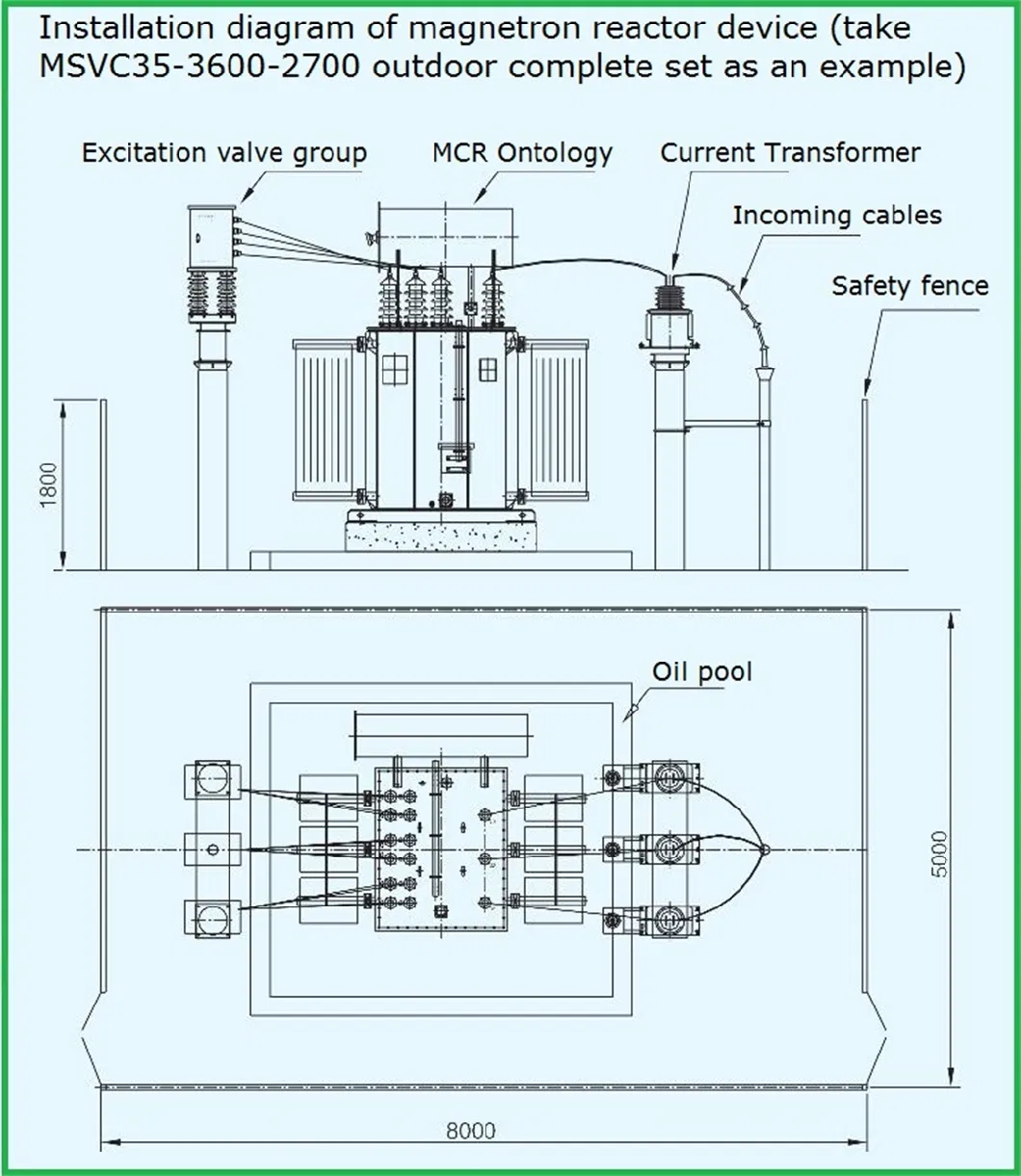

4. Flexible installation methods, both outdoor and indoor installations are available. Small footprint, high reliability, maintenance-free, and long service life.

5. Using multi-CPU parallel processing technology, high degree of automation, can realize various perfect control and protection functions of MCR and FC branch, switch online monitoring, harmonic measurement and control, etc., and can also realize various data transmission and " four" Remote" function. The operation is simple and the user interaction is friendly and convenient.

Application area:

MSVC type dynamic reactive power compensation device is mainly used in 6-220KV power system, which can realize reactive power dynamic compensation, improve power factor, stabilize voltage, and filter harmonics at the same time to improve the power quality of power grid. The device is currently widely used in coal, electrified railways, steel, wind power and other industries, and the power saving effect is obvious.

1. Electric arc furnace

Due to the unstable arc resistance and unbalanced three-phase, the electric arc furnace is mainly harmful to the power grid as follows: the generated Noble components are abundant and the content is large, and the main Noble current components are 2-7 times, among which 2, 3, and 5 times are the largest, the derivative grid is seriously unbalanced in three-phase, negative sequence current is generated, there is serious voltage flicker, and the power factor is low.

The way to completely solve the above problems is that the user must install a dynamic reactive power compensation device with fast response. The MSVC system has a fast response time and can fully meet the strict technical requirements. It can quickly provide reactive current to the electric arc furnace and stabilize the bus grid voltage, increase the output of the active power of the system, improve the production efficiency, and minimize the impact of flicker. The phase-splitting compensation function of MSVC can eliminate the three-phase unbalance caused by the electric arc furnace, and the filtering device can eliminate harmful high-order Noble waves and improve the power factor by providing reactive power to the system.

2. Long-distance power transmission

The power system is currently trending towards high-power grids, long-distance power transmission, and high energy consumption, forcing the transmission and distribution system to increase improvement measures. MSVC can significantly improve the power transmission and distribution performance of the power system, that is, under different power grid conditions, in order to maintain a balanced voltage, MSVC can be installed in one or more appropriate positions in the power grid to achieve the following purposes to stabilize the weak grid system. Voltage: Reduce transmission loss, increase transmission capacity, maximize the efficiency of the existing power grid, increase the transient steady state limit, increase damping under small disturbances, and buffer power oscillations.

3. Rolling mill system

The rolling mill is a reactive impact load, which has the following effects on the power grid: low power factor: causing voltage fluctuation and voltage drop, in severe cases, the electrical equipment can not work normally, reducing production efficiency: harmful high-order harmonics will be generated in the transmission device of the load , mainly the high-order harmonics represented by the 5th, 7th, 11th, and 13th times, which will cause serious distortion of the grid voltage. The MSVC device can solve the above problems well , keep the bus voltage stable, filter out the harmonics, and improve the power factor.

4. Coal mine hoist

Coal mine hoists are mostly driven by DC motors, which have a short working cycle, fast response speed, and large reactive power fluctuations. During operation, they will have the following effects on the power grid: cause grid voltage drop and voltage fluctuations, low power factor, and rectifier devices will produce a lot of high Sub-harmonic, fast response of MSVC device can perfectly solve the above problems.

5. Wind farm

In wind farms, the voltage and reactive power fluctuate greatly under the influence of wind speed, and part of the inductive reactive power is often required to compensate the line charging power. If a fixed or graded switching capacitor bank is used to compensate the system reactive power and improve the power factor, this This method can only provide capacitive reactive power, but cannot achieve fast dynamic adjustment with the change of wind speed, which is easy to cause reactive power to be sent back to the system, increase the voltage, and endanger the stability of electrical equipment and system. The MSVC system can quickly and accurately perform capacitive and inductive reactive power compensation, which can completely solve the problem of reactive power reversal while stabilizing the busbar voltage and improving the power factor. And when the new MSVC system is installed, the original fixed capacitor bank can be fully utilized, and only the magnetron reactor can be added, which can achieve good results with less investment and become a suitable choice for improving the power quality management of wind farms.

6. Electric locomotive power supply

The electric locomotive transportation mode not only protects the environment, but also causes serious "pollution" to the power grid. The single-phase power supply of trams and locomotives causes serious three-phase imbalance and low power factor of the power supply network, and generates negative sequence current. The current way to solve this problem is to install MSVC at the appropriate position along the railway line to improve the power factor and solve the three-phase unbalance.

Product operating environment and ordering instructions

Customers should provide the following relevant parameters and technical requirements when ordering

1. System diagram and parameters: equipment rated voltage, rated current, operating voltage, etc.;

2. The equipment always has power, average power factor, target power factor, or reactive power compensation capacity required during normal operation;

3. Line entry method, use environment conditions, order quantity, delivery time, delivery method, transportation method, etc.;

4. Users can order according to the model, capacity, specification and quantity provided by our company, or provide parameters and requirements, and our company can design and determine the specifications and models;

5. Installation site: indoor, outdoor, size;

6. Other special technical requirements.

Normal use conditions:

1. Indoor and outdoor use;

2. The altitude is generally not more than 1000m;

3. Ambient temperature: -30ºC ~ +50ºC;

4. Relative humidity: the daily average does not exceed 95%, and the monthly average does not exceed 90%;

5. Installation site: no severe mechanical vibration, no harmful gas and steam, no conductive or explosive dust;

6. Anti-pollution ability: the creepage distance of external insulation is not less than 25mm/kV (relative to the higher operating voltage of the system);

7. Earthquake: the intensity does not exceed 8 degrees;

8. Wind speed: < 35m/s.

Note: The anti-pollution ability of the plateau and special environmental products shall be negotiated separately.

Product realshot

A corner of the production workshop

Product packaging