- Overview

- Detailed Photos

- Product Parameters

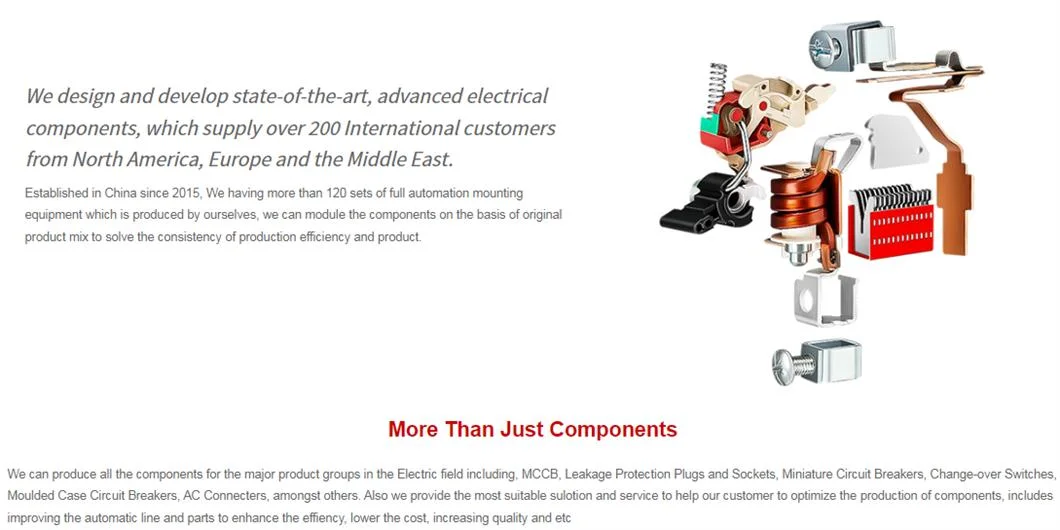

- Company Profile

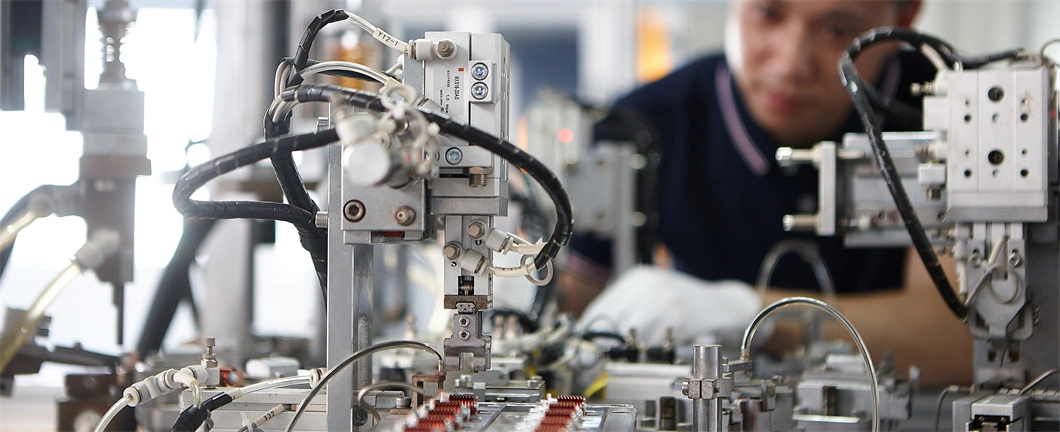

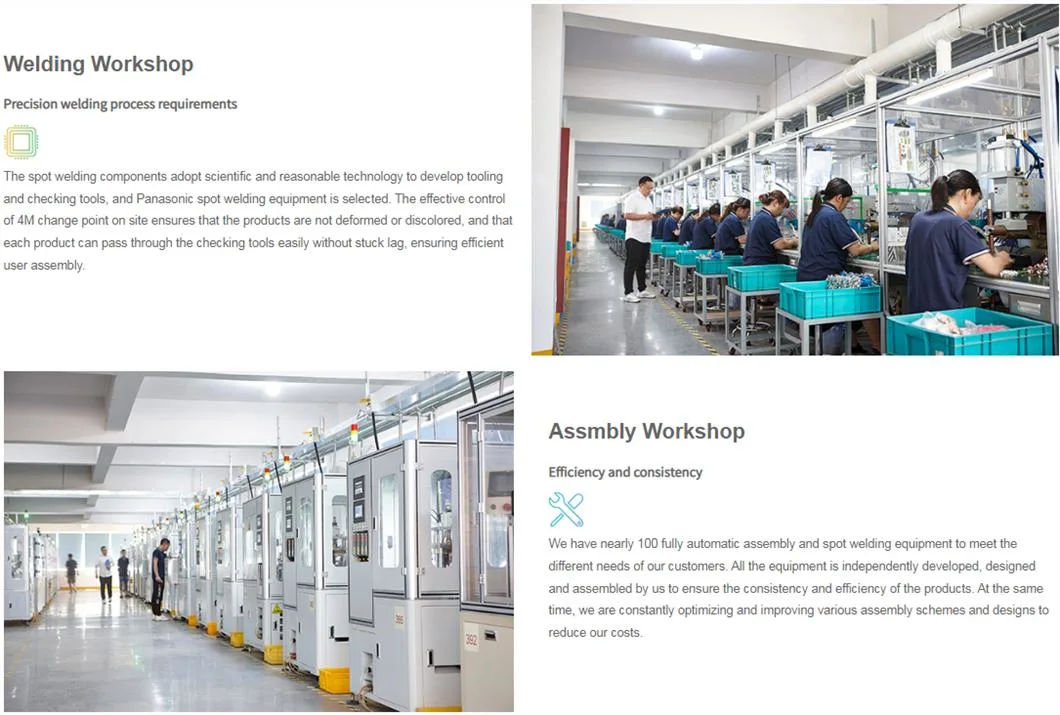

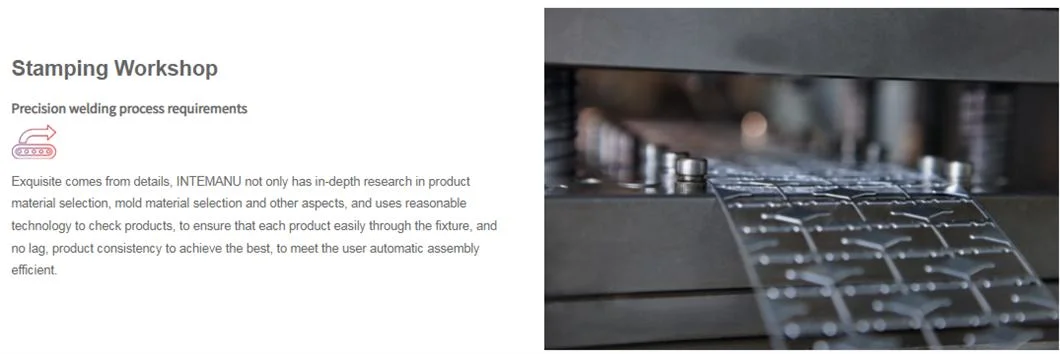

- Facilities

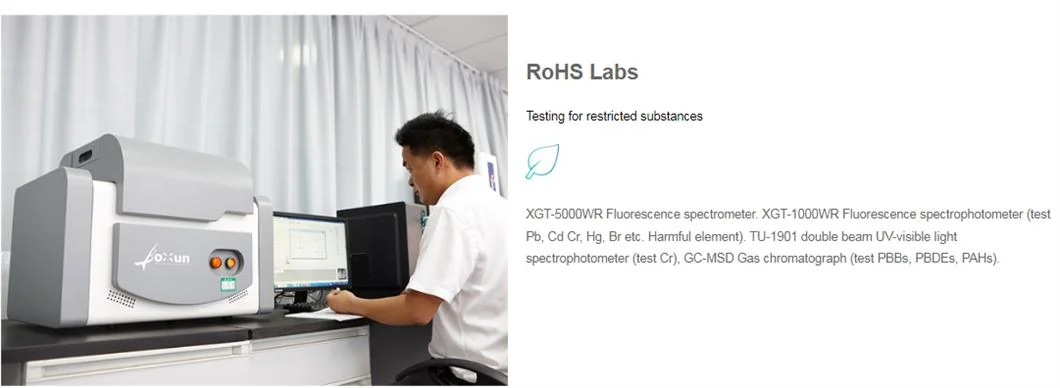

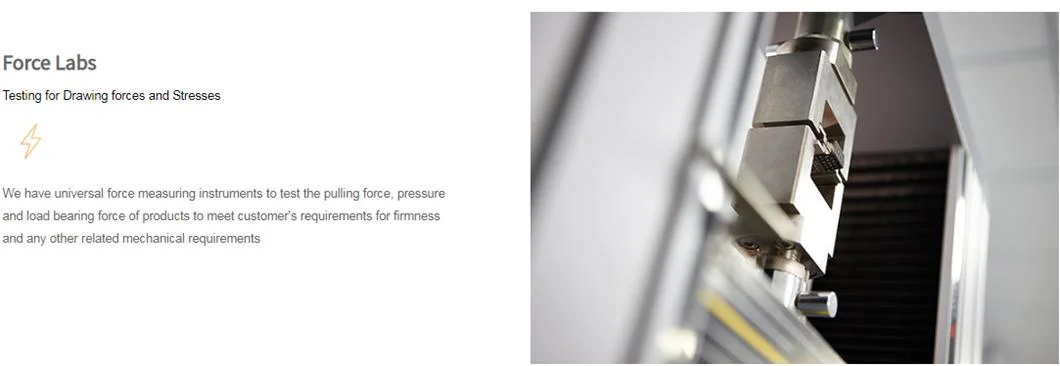

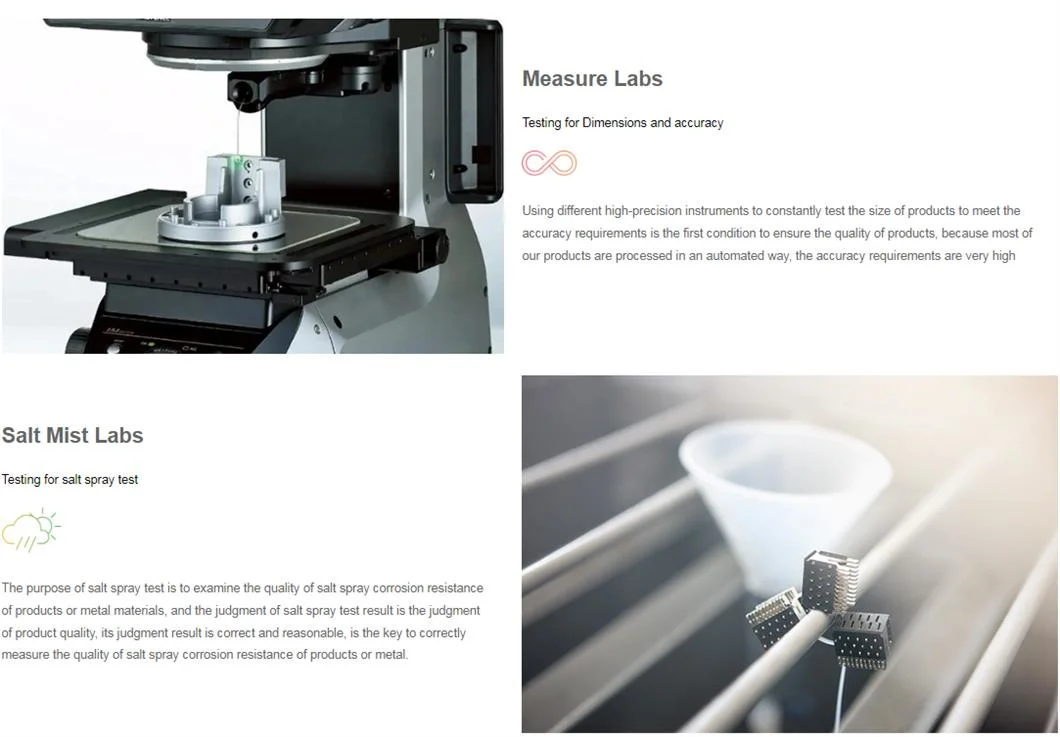

- Laboratory

- Our Advantages

- FAQ

Basic Info.

Product Description

| MODE NO.: | XMA4GS |

| MATERIAL: | IRON DC01, BMC |

| NUMBER OF grid PIECE(pc): | 19 |

| WEIGHT(g): | 1825 |

| SIZE(mm): | 146*69*141.5 |

| CLADDING & THICKNESS: | NICKLE |

| PLACE OF ORIGIN: | BLUE WHITE ZINC |

| APPLICATION: | ACB, air circuit breaker |

| SAMPLE CHARGE: | FREE, CUSTOMER NEED TO PAY FOR THE FREIGHT |

| OEM & ODM: | AVAILABLE |

| PACKING: | POLY BAG, CARTON, WOODEN PALLET AND SO ON |

| PORT: | NINGBO, SHANGHAI, GUANGZHOU |

| MOQ: | IT DEPENDS |

| SHIPPING: | BY SEA OR AS REQUIRED |

| INSTALLATION: | MANUAL & AUTOMATIC |

| PRODUCTION CAPACITY: | 30,000,00 PCS PER MONTH |

| MOULD CUSTOMIZATION: | AVAILABLE |

1. Product Customization

Custom arc chute are available upon request.

A. How to customize the arc chute?

Customer offers the sample or technical drawing, our engineer will make few samples for testing in 2 weeks. We will start making the mould after customer checks and confirms the sample.

B. How long we take to make a new arc chute?

We need 15 days to make sample for confirming. And making a new mould needs about 45 days.

2. Mature Technology

A. We have technicians and toolmakers who can develop and design all kinds of arc chamber according to different requirements in the shortest time. All you need to do is to offer samples, profile or drawings.

B. Most of the productions are automatic which can lower the cost.

3.Complete Range of Products

Full range of arc chambers for miniature circuit breakers, moulded case circuit breakers, earth leakage circuit breaker and air circuit breakers.

4.Quality Control

We control the quality by many inspections. Firstly we have a incoming inspection for the raw material. And then process inspection for the rivet and stamping. Finally there is final statistical audit which consisting the measurement of sizes, tensile test and coat examine.

1.Q: Are you trading company or manufacturer ?

A: We are manufacturer and specializing in circuit breaker accessories.

2.Q: How long is your delivery time?

A: Normally 5-10 days if there are goods in stock. Or it will take 15-20 days. For customized items, the delivery time depends.

3.Q: What is your terms of payment ?

A: 30% T/T in advance ,and the balance before shipment.

A: Yes.We can offer customized products and packing ways can be made according to customer's requirement.

5.Q: Can you offer mould making services?

A: We have made many mould for different customers for years.

6.Q: How about the guarantee period?

A: It varies according the different kinds of product. We can negotiate it before place an order.

7.Q: What is your production capacity?

A: We can produce 30,000,000 pcs every month.

8.Q: How about the scale of your factory?

A: Our total area is 7200 square meter. We have 150 staffs, 20 sets of punch machines, 50 set of riveting machines, 80 sets of point welding machines and 10 sets of automation equipments.

9.Q: What tests do you have to confirm the quality of the arc chamber?

A: We have a incoming inspection for the raw material and process inspection for the rivet and stamping. There is also final statistical audit which consisting the measurement of sizes, tensile test and coat examine.

10.Q: What is the cost for the customized mould? Will it be returned?

A: The cost varies according to the products. And I can be returned depends on agreed terms.