Basic Info.

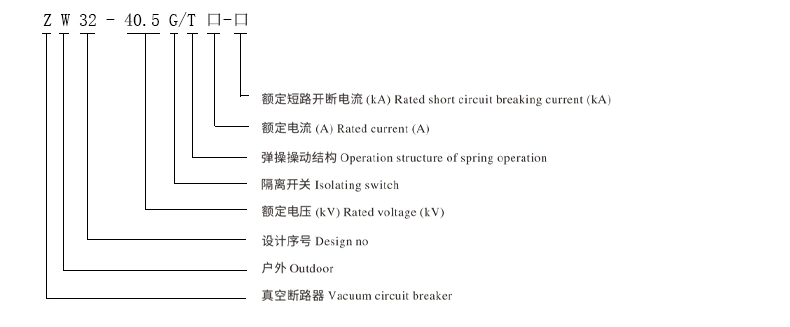

Model NO.

ZW32-40.5KV

Type

Circuit Breaker

Function

Conventional Circuit Breaker, Circuit-Breaker Failure Protection, Overcurrent Protection

Certification

ISO9001-2000

Transport Package

Wooden Box

Trademark

zhuowoma

Origin

China

HS Code

8535210000

Production Capacity

10000 Pieces / Year

Product Description

Overview

Cireuit breakers meet technical standards such asGB1984-2003,DL/T402-2007 and IEC60056.

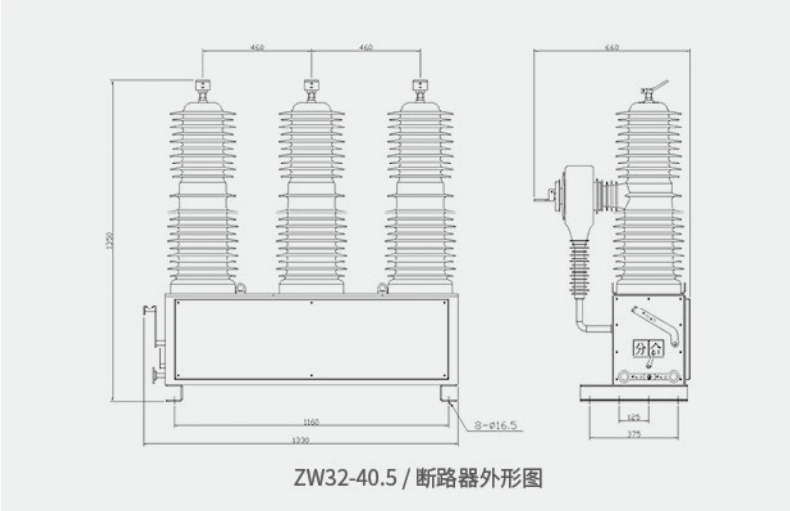

Dimensions and mounting dimensions

Dimensions and mounting dimensions  Working principle of circuit breaker

Working principle of circuit breaker 1. Arc extinguishing principle:

Zw32-40.5 outdoor high voltage vacuum circuit breaker adopts vacuum arc extinguishing chamber, with vacuum as arc extinguishing and insulating medium, with high vacuum degree. When the moving and static contacts operate the mechanism

Vacuum arc will be generated between contacts when charged break under the action. At the same time, due to the special structure of contacts, appropriate longitudinal magnetic field will also be generated in the gap between contacts to promote vacuum electricity

The arc is kept diffused and the arc burns evenly over the contact surface, maintaining a low arc voltage and residual ions, electrons and metal vapors in microseconds when the current naturally crosses zero

It can be combined or condensed on the contact surface and shield cover in order of magnitude of time, and the dielectric insulation strength of the arc chamber fracture can be quickly restored, so that the arc can be extinguished to achieve the purpose of breaking. by

The longitudinal magnetic field is used to control the vacuum arc, so the vacuum circuit breaker has strong and stable breaking current capacity.

2. Electric energy storage

The motor applies the output torque to the pinion of the mechanism and drives it to the main shaft. On the large sprocket, thus driving the arm rotation, so that the closing spring energy storage. When the screw on the arm is pressed down the travel is opened

When off, cut off the motor power, spring energy storage is completed.

3. Manual storage:

By rotating the output shaft of the mechanism, the pinion on the output shaft will transfer the rotating torque to the big gear which is fully engaged by the pinion, so as to drive the turn arm to rotate and store energy of the closing spring.

4. Closing electromagnet operation:

After the mechanism receives the closing signal, the moving core direction of the electromagnet is closed. Move up, push the closing tripping rod to move up, so that the closing half shaft rotates counterclockwise. Release to close zhi son

Constraint, at the same time, closing zhi son by roller oppression and counterclockwise rotation, remove energy storage maintenance, located in the main shaft of the CAM due to closing spring contraction force impact force, hit. On the manual

The rocker arm on the energy storage shaft (output shaft) drives the switch through the connecting rod to complete the closing operation.

5. Manual operation

Mounted on closing half shaft. When the fork turns counterclockwise, it drives the closing half shaft to rotate counterclockwise. This produces the same effect as closing the electromagnet operation.

6. Reclosing operation:

After releasing the energy of the energy storage spring, the mechanism completes the closing operation. In the closed state, the mechanism carries out the energy storage operation again. After completing the energy storage operation, the mechanism is in the closed and stored energy state

Once the correct signal is received in this state, the mechanism can realize automatic reclosing operation.

7. Split solenoid operation:.

After the mechanism receives the break signal, the break electromagnet moving core direction. Move up to push the release lever in direction. Move up to make the half shaft of brake rotate counterclockwise. Releasing the switch

Constraints. At the same time, the brake zhi son by the roller and counterclockwise rotation, rocker arm by the switch part of the brake spring thrust and counterclockwise rotation, so as to complete the brake operation.

8. Manual operation:

Mounted on the brake half shaft. When the fork on the counterclockwise rotation, driving the brake half axis along the counterclockwise direction, so as to produce the same effect as the brake electromagnet operation.

9. Overcurrent tripping operation:

When the overcurrent coil in the overcurrent tripping device passes through the specified tripping current, the electromagnet moves and the push rod pushes the tripping rod. Make the half shaft of the opening brake rotate counterclockwise to release the engagement of the opening brake

The beam thus produces the same effect as the switching electromagnet operation to complete the current tripping operation of the circuit breaker.

Technical parameter

| number | project | Company | data |

| 01 | Rated voltage | kV | 40.5 |

| 02 | Rated current | A | 630/1250 |

| 03 | Rated frequency | Hz | 50 or 60 |

| 04 | Power frequency withstand voltage for 1min (wet) (dry) interphase, ground / fracture | kV | 80 95/95 |

| 05 | Lightning impulse withstand current (peak value) phase to phase, ground to ground / fracture | kV | 185 |

| 06 | Rated short-circuit breaking current | kA | 25/31.5 |

| 07 | Rated short-circuit making current (peak) | kA | 63/80 |

| 08 | Rated peak withstand current | kA | 63/80 |

| 09 | 4S short-time withstand current | kA | 25/31.5 |

| 10 | Rated operating cycle | Minutes -0.1s one-in-one minute -3s one-in-one minute -6s one-in-one minute -60s Recovery | |

| 11 | Rated short circuit breaking times | times | 30 |

| 12 | Mechanical life | times | 10000 |

| 13 | Mechanism control voltage | V | AC/DC220 |

| 14 | 1min power frequency withstand voltage of secondary circuit | kV | 2 |

| 15 | Contact opening distance | mm | 16±1 |

| 16 | Contact overtravel | mm | 4±0.5 |

| 17 | Opening speed | m/s | 1.4-1.8 |

| 18 | Closing speed | m/s | 0.4-0.8 |

| 19 | Contact closing bounce time | ms | ≤5 |

| 20 | Center distance between phases | mm | 460±2 |

| 21 | Asynchrony of three-phase opening and closing | ms | ≤2 |

| 22 | Conductive circuit resistance of each phase | μΩ | <80 |

| 23 | Closing time | ms | ≤100 |

| 24 | Opening time | ms | ≤50 |

| 25 | weight | Kg | 270 |